Advanced Structural Research and Testing Laboratory

“Fostering Innovation with Versatile Advanced Structural Research Facilities”

Our Structural Laboratory at the Centre for Infrastructure Engineering (CIE), located at the Penrith Campus (Kingswood), holds a wide range of facilities and testing equipment to support research and consultancy activities in structural engineering.

Strong Floor Area

Our strong floor, spanning an area of 16 x 8 meters, is designed to accommodate the diverse experimental needs of researchers and industry partners, allowing for testing of specimens reaching heights of up to 3 metres. Key features of our strong floor include:

- Static and Dynamic Loading Capacities: A static compressive load of up to 3,000kN (300 tonnes) and dynamic fluctuating loads of up to 400kN (40 tonnes) at 2-3 Hz can be accommodated.

Strong Floor, 8m x 16m, and associated Testing Rigs

- Versatile Setup Options: Our loading frames and available gear provide us with the capability to create various types of setups in different directions, accommodating loadings of up to 5000kN (500 tonnes) with actuators ranging from 150kN to 3000kN (300 tonnes).

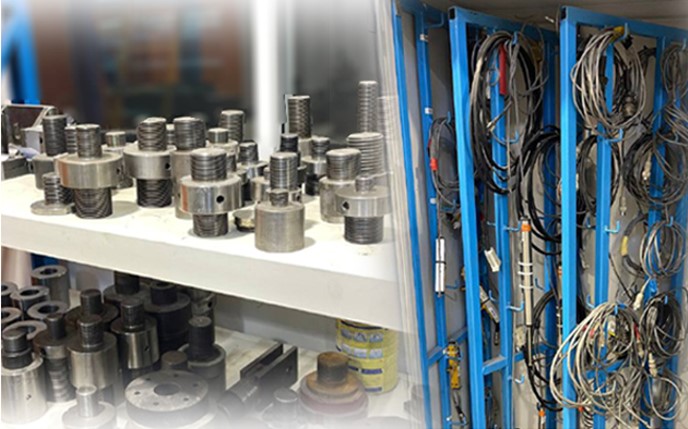

Available gear for accommodating different test setups

- Range of Sensor Options: Diverse selection of sensors, including Load Cells, Linear Potentiometers (LP), LVDTs, lasers, transducers, strain gauges, thermocouples, laser scanner, and more, for reliable and accurate data acquisition.

Available gear for accommodating different test setups

General experimental tests that have successfully been conducted include:

- Compressive strength testing of Concrete Filled Tubes (CFT) columns and Pumpable Cribs.

- Shear strength testing of connections, drywalls, and concrete walls.

- Tensile strength testing of high-capacity bolts.

- Three-point and four-point bending testing of steel, concrete, timber and composite beams, composite floors etc.

- Fatigue testing on sleepers.

- Pull-out testing of fasteners.

- Structural testing of pallet racking.

High Capacity Hongshan Multipurpose Testing Machine

The Hongshan 10 Meganewton (10,000kN, 1000 tonnes) testing machine stands as one of the largest and highest capacity facilities of its kind in Australia and globally, at the WSU Structural Laboratory.

This machine has been used for various tests on high-strength construction materials commonly employed in infrastructure projects, including pumpable cribs, Concrete Filled Tubes (CFT), and modelled bridge decks, slab systems, concrete walls etc.

It can accommodate samples up to 4 meters in height, with a platen measuring 1m x 1m and a stroke of up to 300mm. It has capability of not only test specimens in compression, but also in shear, as well as alternating load.

Hongshan 1000 tonnes multipurpose testing machine

INSTRON 8506 Universal Testing Machine

This universal testing machine has a load-bearing capacity of 3000kN (300 tonnes). It is capable of accommodating samples with a height of up to 4 meters with stroke of up to 300mm.

The Instron 8506's high load capacity, platen size, diverse support options ranging from pin to rigid, and its relatively tall and adjustable structure, make it well-suited for a wide range of testing applications such as pallet racking, masonry wall, column tests, etc across various industries.

INSTRON 8506 UNIVERSAL TESTING MACHINE

Morris Heckenburg Furnace with Universal Testing Machine

This universal testing machine with gas furnace can accommodate fire/load tests on specimens up to 2000kN (200 tonnes) load-bearing capacity at temperatures up to 800 degrees Celsius.

This machine has been used for fire testing of various novel composite columns and different material testings, can be programmed for the temperature with gas furnace internal chamber of about 600 x 600 x 850 mm.

It can accommodate samples up to 1.8 meters in height, with a platen measuring 250x250mm.

Morris Heckenburg Furnace with Universal Testing Machine

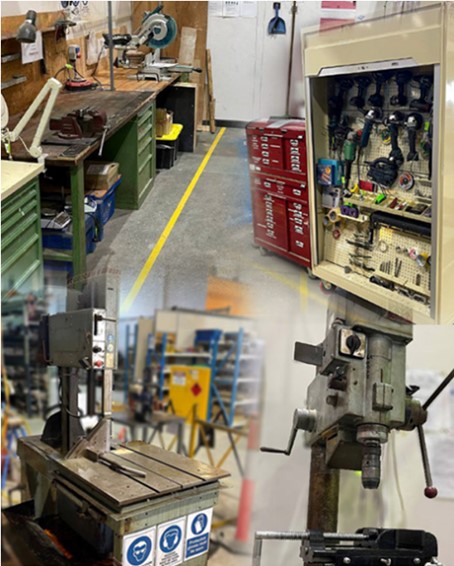

Structural Workshop

Our equipment and resources are adaptable and able to handle a variety of tasks from heavy engineering projects to delicate work with small components. We provide forklifts capable of lifting loads up to 2.5 tonnes at a load centre of 600mm, as well as overhead cranes for handling heavy items weighing up to 6 tonnes.

Additionally, we have a wide range of standard industrial machines, including large drills, various saws, grinders, and woodworking equipment.

Some facilities and workshops

Discover our successful experimental tests and check our Consulting Projects & Capabilities for more information.

If you require more information about our services, please contact:

Professor Bijan Samali

Senior Professor of Structural Engineering

Commercial services

Phone: +61 2 4736 0263

Mobile: +61 419 223 695

Email: B.Samali@westernsydney.edu.au