Materials Testing Laboratory

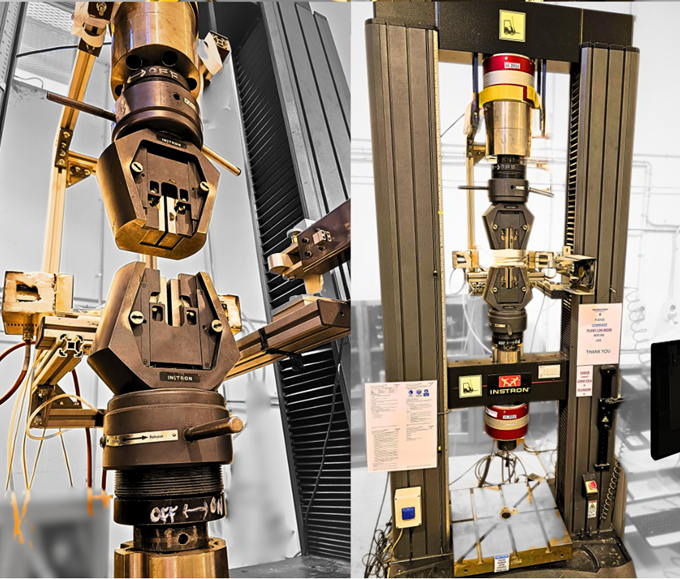

INSTRON 5985 Universal Testing Machine

This machine is a state-of-the-art INSTRON model with a 250KN load cell capacity. It is commonly used for material testing to measure mechanical properties, including tensile, compression, bending strength, fatigue test, and other characterisation of different materials such as concrete, polymers, composites, and textiles.

- Specification:

- 250KN static compressive load capacity.

- Load measurement accuracy to +/-0.5% of reading down to 1/1000 of load cell capacity.

- Test Platen Size: 500 x 550mm which can be extended.

- Extensometers with 50mm gauge length.

- Equipped with Bluehill® Universal software, this system offers combined loadings capabilities, ensuring precise management of test parameters and data acquisition.

- Supports additional sensors, including LPs and strain gauges.

- Supports various size and type of jaws, grips, and fixtures.

- Temperature chambers 50 x 50mm, testing materials up to 1,200°C.

INSTRON 5985 Universal Testing Machine

Gear Available for Different Test Setups

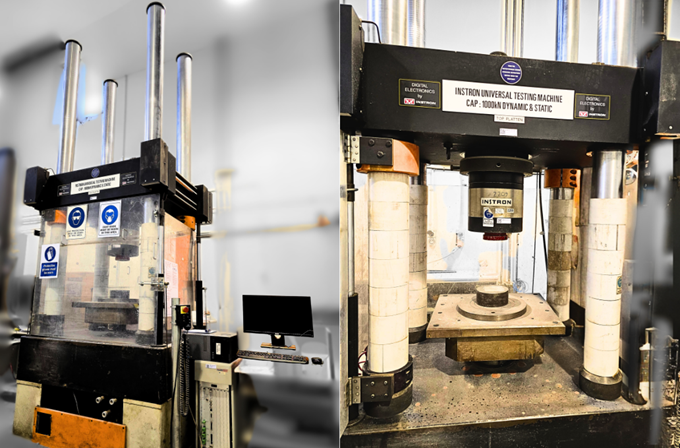

INSTRON 8036 Universal Testing Machine

The INSTRON 8036 is a universal testing machine with a 1000kN axial static compressive force capacity and four adjustable-height columns. It is highly versatile and suitable for testing various assemblies, materials, and different sample sizes. Typical applications include cube/cylinder sample tests, MoE tests, Brazilian tests, aggregate crushing tests, steel stub column tests, and other material characterisations.

- Specification:

- 1000kN static compressive load capacity.

- Standard concrete cylinder tests of up to about 100MPa concrete strength.

- Test Platen Size: 600 x 600mm, which can be extended.

- Sample height of up to 1800mm.

- Supports various grips, jigs, fixtures, and accessories.

- Equipped with Bluehill® Universal software for force or displacement-control loading and data management.

INSTRON 8036 Universal Testing Machine

MTS 5000 High-Capacity Material Testing Machine

The MTS 5000 is a high-capacity material testing machine with a 5000kN axial static compressive force capacity. It is ideal for testing various high-strength materials and supports both force and displacement control loading for versatile testing applications, accommodating samples with a low range of size.

- Specification:

- 5000kN load-bearing capacity.

- Standard concrete cylinder tests of over 100MPa concrete strength.

- Sample height up to 500mm.

- Test platen size: 250 x 250mm.

- Programmable force and displacement control.

- Supports additional sensors, including LPs and strain gauges.

- Suitable for high strength material characterizations such as high-strength concrete samples.

MTS 5000 High-Capacity Material Testing Machine

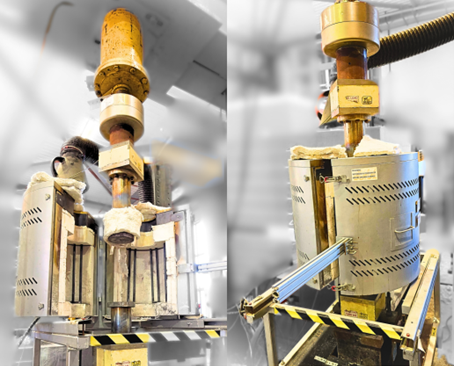

Morris Heckenberg Furnace with Universal Testing Machine

The Morris Heckenberg furnace with Universal Testing Machine is designed for combined fire and universal load tests on specimens with a load-bearing capacity of up to 2000kN at temperatures up to 800 degrees Celsius. This versatile machine is suitable for testing various novel composite columns and different materials.

- Specification:

- 2000kN load-bearing capacity.

- Temperature ranges up to 800 degrees Celsius.

- Gas furnace internal chamber dimensions: 600 x 600 x 850mm.

- Sample height up to 1800mm.

- Test platen size: 250 x 250mm.

- Programmable temperature, force, and displacement control.

- Supports sensors, including thermocouples.

- Suitable for fire testing of composite columns and other material characterisations.

Morris Heckenberg Furnace with Universal Testing Machine

The Bore Split Furnace

The Bore Split tube furnace is designed for fire and universal loading tests, featuring a temperature capacity of 1200°C and a loading capacity of 1000kN. It is suitable for fire resistance testing of small-scale samples, including cylinder tests and evaluating the mechanical properties of various materials at high temperatures.

- Specification:

- 1000kN load-bearing capacity.

- Temperature range up to 1200 degrees Celsius.

- Sample sizes up to 150mm D x 300mm H

- Programmable temperature, force, and displacement control.

- Supports additional sensors including thermocouples.

- Suitable for fire testing of composite material characterizations.

The Bore Split Furnace

Director of Materials at the Centre for Infrastructure Engineering

Phone: +61 2 4736 0064

Email: z.tao@westernsydney.edu.au