- Industry Collaborators

- People

- News

- Research News

- Doctoral Research

- Research Projects

-

Roundtables

- - Academic Roundtable February 2023

- - Academic Roundtable September 2020

- - Academic Roundtable September 2019

- - Academic Roundtable April 2019

- - Academic Rountable November 2018

- - Inter-university Academic Rountable November 2018

- - Community of Practice Roundtable June 2021

- - Community of Practice Roundtable June 2020

- - Colloquium on Managing Construction in the 21st Century

- Community of Practice

- Future Constructors

- Digital Media Repository

- Training

Academic Rountable November 2018

Conversation Theme

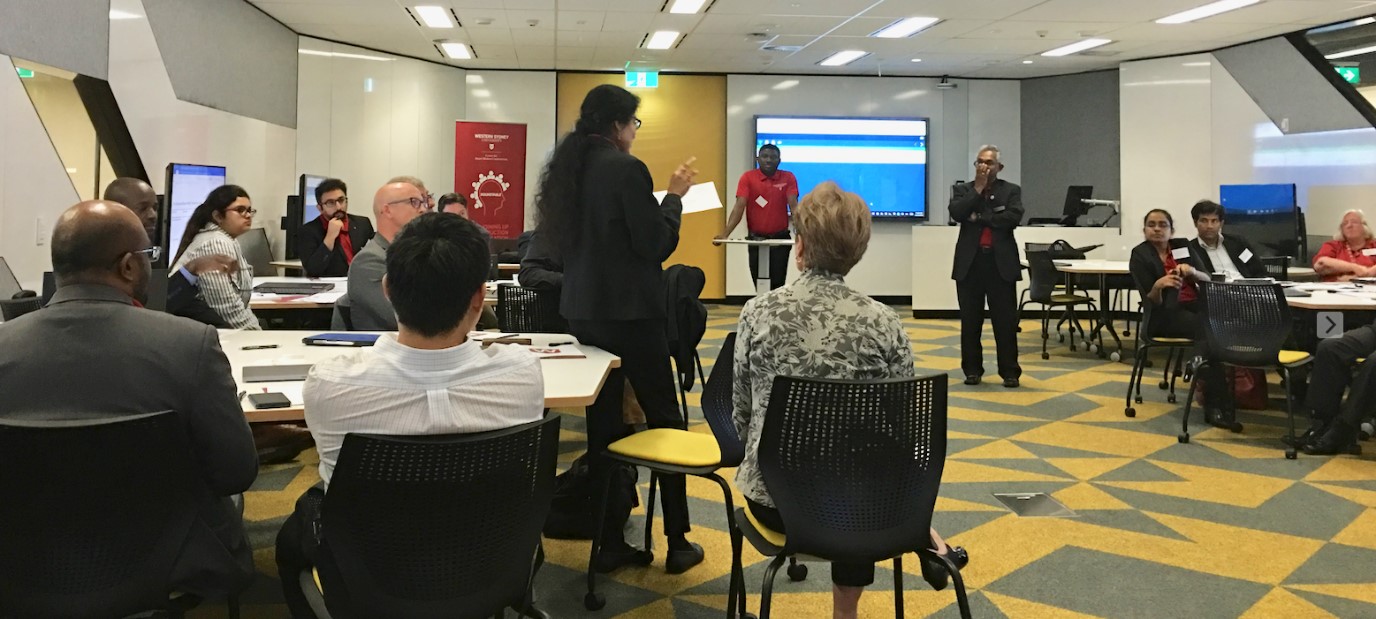

The inaugural Centre for Smart Modern Construction (c4SMC) inter-university roundtable brought together nine universities to discuss the future of construction in Australia and how each was developing new insights into an industry that is slowly embracing the fourth industrial revolution (colloquially referred to as Industry 4.0 and in our context, Construction 4.0). The focus was on how our institutions are preparing to ensure tomorrow’s construction professionals are future ready.

The Roundtable theme on this occasion invited observations on how developments off-site were likely to impact the future of on-site organisation, work packaging, skilling, construction effectiveness, industry governance, sustainability and the resilience of tomorrow’s built-world.

A copy of a discussion paper shared with delegates is available on the c4SMC website.

Follow this link to find speaker presentations in PDF form, available for download.

Welcome to Delegates

The welcome to delegates was given by Dr Robert Osei-Kyei on behalf of the academic team and Professor Kerry London – Acting Dean of the School of Computing, Engineering and Mathematics. Robert acknowledged the first peoples and their historical connections to the many places from where colleagues had travelled, including New Zealand. He pointed to a new history taking shape as Parramatta evolves into the Central City of the greater-Sydney conurbation, making it Australia’s construction hot-spot. He acknowledged industry supporters of c4SMCand their contribution to the many initiatives and engagements started by the Centre during 2018.

Professor London welcomed the many trusted, long-standing colleagues as well as our new-comers and provided a context for the day identifying the need for collaboration across government, academia and industry to address the many challenges facing the construction industry globally. At the forefront of these changes are the industry’s need to embrace the digital economy, new digital technologies, the progressive industrialisation of construction and the reality of globalisation as construction’s future is defined by the integration of new skills, automation, supply-chain evolution and new teaching models. Kerry pointed to the diversity of research collaborations the university has and the innovative non-traditional ways this work is being with c4SMC as an example.

Kerry drew on a range of reports[i]and study groups that her work has embraced in recent times and expressed a hope that today's roundtable will lead to new collaborations - ones that join up the best that all have to bring - in order to accelerate the preparation of tomorrows constructors, the enterprises they will lead and our academics, so that we may be future ready and to continue to thrive.

The Roundtable Conversations

Centre Director, Professor Srinath Perera spoke to the idea behind the Centre’s purpose and Smart Modern Construction (SMC). SMC is defined as construction that embraces smart and modern technologies to develop innovative and performance enhancing components, products, systems and processes. He said, the SMC Research Agenda is set within the context of Industrialisation that is happening. SMC is influenced by Digitalisation, Globalisation, Sustainability and Resilience and the Centre’s research aims to resolve issues in these broader themes”.

Srinath provided a brief overview of the research projects that the Centre has commenced, discussing the convergence of technologies and how “cyber physical interfacing”- the real time connection of components, was bringing innovative possibilities including analytics that provide new abilities and direction to manage procurement and supply chains. He pointed to the deliberations that confronted the roundtable that included;

- How do we improve productivity?

- Is more off-site the full solution?

- Will digitalisation deliver the step-change expected?

- What happens where construction moves 80% off site? What will be the

- Impact on enterprises?

- Impact on the industry?

- Impact on procurement?

- Impact on skills?

Adjunct Professor David Chandler spoke briefly to the circulated Roundtable theme and why it was so important for pre-competitive engagements between academia and industry to share in developing the base-line knowledge and performance benchmarks that would be needed to observe successful industry transformation. These engagements were necessary to develop clear direction to policy makers and those invested in the industry’s future resilience. David is the Industry Engagement Lead for c4SMC. He stressed the need for properly informed and engaged research to be the product of c4SMC as it progressively finds its way into the teaching academic program. He stressed that the making of tomorrow’s built-world would involve more multi-discipline collaboration across construction, design, engineering, computing, business and law than it has in the past. And he pointed to the need to develop a modern construction narrative that made Construction 4.0 a compelling career choice for future school leavers.

Adjunct Professor David Chandler spoke briefly to the circulated Roundtable theme and why it was so important for pre-competitive engagements between academia and industry to share in developing the base-line knowledge and performance benchmarks that would be needed to observe successful industry transformation. These engagements were necessary to develop clear direction to policy makers and those invested in the industry’s future resilience. David is the Industry Engagement Lead for c4SMC. He stressed the need for properly informed and engaged research to be the product of c4SMC as it progressively finds its way into the teaching academic program. He stressed that the making of tomorrow’s built-world would involve more multi-discipline collaboration across construction, design, engineering, computing, business and law than it has in the past. And he pointed to the need to develop a modern construction narrative that made Construction 4.0 a compelling career choice for future school leavers.

The first of the Academic speakers was the University of Technology, Sydney’s Professor Perry Forsythe. Perry has an applied construction background, so he joins up the practical and theoretical by drawing on his deep knowledge of materials, processes and construction organisation. He has been at the forefront of timber building construction in Australia through work for organizations such as Forest Wood Products Australia and their Wood Solutions research.

Perry’s roundtable presentation addressed 5 project based themes which looked at construction productivity;

Project 1: Can timber be cost/time/design competitive? Outcome – Yes, but:

- Must design for timber – collaboration is important

- Recognition of cost sensitivity parts

- Need for speed - time dependent prelim. costs (18-20%) must be slashed

Projects 2 & 3: Installation productivity of Prefab Timber (time/motion study)

- Install rates m2/hour - crane cycle defines productivity onsite,

- Informs DFMA principles and identifies where time is lost

Project 4: Logistics/RFID/Object tracking provides:

- Monitors flow/waste and measures productivity (speed)

- Object specific instruction and planning install sequencing

Project 5: Gottstein Fellowship - State-of-art in Production line techniques

- Mass vs Customizability and File-to-factory techniques

- Minimizing WIP, Inventory, Machine time to assure delivery certainty for clients

He concluded his presentation by sharing thoughts on the need for construction to adopt a platform led systematisation. This was not unlike the vehicle industry but with the pressing issue of “how to make it work in construction”? Possibly the consideration of the appropriate ratio of design flexibility vs predetermined design and inputs is the way forward, with models that currently exist being implemented to help this process.

He concluded his presentation by sharing thoughts on the need for construction to adopt a platform led systematisation. This was not unlike the vehicle industry but with the pressing issue of “how to make it work in construction”? Possibly the consideration of the appropriate ratio of design flexibility vs predetermined design and inputs is the way forward, with models that currently exist being implemented to help this process.

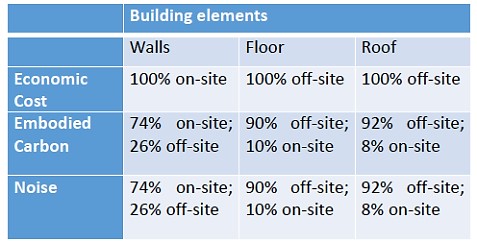

Dr Ahmed Hammad Lecturer in the Faculty of the Built Environment at the University of NSW spoke to “Optimising the use of Prefabrication” on projects. He cited the optimisation of prefab at the project level to be subjective to project scopes. Components such as slabs, vertical structure elements, facades, partitions, stairs and sanitary units the obvious areas in which to concentrate and within the mix of construction typologies involving;

- Standard buildings (completely off the shelf)

- Customised buildings (use standard components and systems)

- Hybrid buildings (using standard components and sub-assemblies)

- Bespoke buildings (no standardised systems and no standard interfaces)

Ahmed also discussed a framework for sustainable procurement which considered the economic, environmental and social implications of clients embracing prefabrication. He felt that the available research tools were not appreciated by industry and understanding their potential could help in lifting the optimisation of prefabrication in the construction industry. He spoke to this table which helped explain the potential benefits for key elements being adopted for prefabrication.

Ahmed also discussed a framework for sustainable procurement which considered the economic, environmental and social implications of clients embracing prefabrication. He felt that the available research tools were not appreciated by industry and understanding their potential could help in lifting the optimisation of prefabrication in the construction industry. He spoke to this table which helped explain the potential benefits for key elements being adopted for prefabrication.

c4SMC PhD candidate Priyadarshini Das presented an overview of her research into the Business Scenarios that are leading to Construction 4.0. Priya’s work will involve developing a definition for Smart Modern Construction (SMC) and its application to construction enterprises. This will be followed by analysing the characteristics of SMC Enterprises through case studies. The work will evaluate the drivers/ barriers/ key-performance indicators of SMC enterprises through case studies and expert forums. This will then be fed into an SMC Capability Maturity Model (CMM) for SMC enterprises. This project is a high priority for c4SMC supporters with anticipated benefits to industry and the academic teaching program within 3 to 5-years.

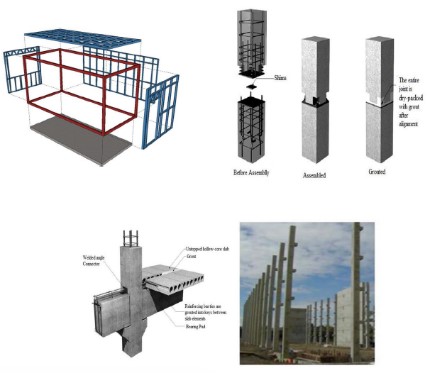

Dr Tharaka Gunawardena from the University of Melbourne presented on “Onsite to Offsite”. Tharaka is a Research Fellow in the University’s ARC CAMP.H program in the Department of Infrastructure Engineering. He works closely with Professor Tuan Ngo who presented at the Centre’s October colloquium. Dr Gunawardena’s presentation addressed the forms of prefabrication being observed by CAMP.H and the role of Head Contractors in achieving timely project delivery. Both Professor Ngo’s and Dr Gunawardena’s work is industry facing and involves frequent overseas and industry conference participations to ensure the most practical insights into developments in global prefabrication are identified and shared in a timely manner.

Associate Professor Tayyab Maqsood is the Associate Dean, Project Management in RMIT’s School of Property, Construction and Project Management. Tayyab’s presentation focused on the Business Impact of Off-site Construction and how RMIT’s Project Management program is preparing its future graduates to anticipate a transforming industry as Construction 4.0 unfolds. His presentation covered the barriers to business modernisation; the value of prefabrication that could deliver more than 7% cost savings (KPMG 2016); the challenges of contractor acceptance when up to 95% of a project is contracted out; the new frontiers of project finance when prefab becomes a major part of project cash flow; and the role of digital technologies in progressing Construction 4.0.

‘Subcontractors are only just beginning to understand these impacts and the implications of retaining old structures in a newly emerging production and technological world’ Goh and Loosemore, 2017

Tayyab then went on to discuss RMIT’s Project Management and practices curriculum which addresses how planning and scheduling for Prefabrication fundamentally change the need for more upfront design time, risk management, stakeholder engagement, quality assurance and compliance, contract administration, site logistics, knowledge management and unlearning.

The morning session addressed ‘on-site to off-site – implications to construction businesses.’ This was drawn together by each of the Roundtables working through a Construction Business Model Transformation Canvas. The conversations addressed issues such as business value propositions, client relationships, potential competitors, supply chains, cost structures, revenue streams and key resources. These insights are invaluable to c4SMC research. The c4SMC academic team collected the roundtable inputs and will prepare a discussion paper which will be shared with attendees.

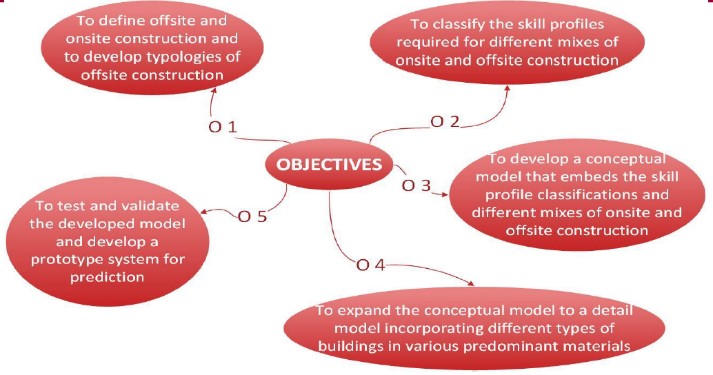

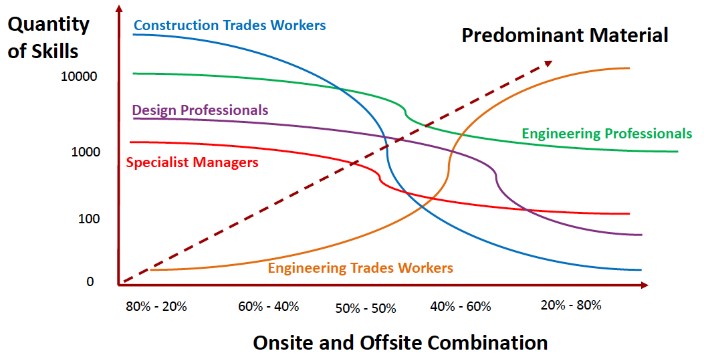

The afternoon roundtable shifted the on-site to off-site conversation to – ‘the implications for construction skill profiles.’ c4SMC PhD candidate Buddhini Ginigaddara provided a disgussion on her research project which addresses profiling the industry’s future skills requirements including: why off-site construction, what skills and why now? Her research aims and objectives; the conceptual model proposed and insights into a detailed model that she and her supervisors envisage were discussed. Buddhini’s work will deliver short term benefits to industry (3 to 5-years), into the academic program and to agencies such as TAFE, WorkSafe, and the Building Professionals Board.

A progress report on this research will be presented at the c4SMC Industry Roundtable in April 2019. Early insights into the implications for on-site construction skilling, as the degree of OSCM increases across a 20 to 80-percent spectrum, will be outlined.

Dr Morten Gjerde from the Victoria University in Wellington shared the drivers and engagements that are taking shape in New Zealand. Morton is the Head of the School of Architecture and was joined at the roundtable by Brenda Lazelle who is the Enterprise Development Advisor in the Research Development Office at Victoria University (VUW). VUW has a strong engagement with organisations like BRANZ, PrefabNZ (CoLab 2018) and others that bring to universities many industry collaborations and research project opportunities. Collaboration was the central theme of Morten’s presentation.

His observations report a fragmented industry slow to adopt change with many continuing to cling to sequential contracts as way of managing risk. The flip-side is that New Zealand’s small size has been factor in early adoption of other technologies. He said housing must drive demand for off-site construction manufacture in NZ as the nation works through the common barriers. Morton spoke to a student led project called the First Light House - pictured. This was a solar decathlon challenge that achieved a wide buy-in from the university and the broader industry. VUW has a well-developed culture around design and research where students tackle industry issues such as jointing, modularity and aesthetics in housing. This work carries over to the circular economy where design focuses on minimizing waste, design for alternative uses at end of life and ‘cradle to cradle’ thinking.

Associate Professor Jasper Mbachu and Professor Craig Langston collaborate in Bond University’s Centre for Collaborative Construction Research (CCCR). Jasper presented the CCCR’s pre-considered thoughts on the Roundtable’s theme ‘From Onsite to Offsite Construction – Implications for Construction Skill Profiles’. He spoke to the key questions for OSCM, the need for new skills, the evolutionary trends of onsite going offsite, the impacted skill categories, the impact on technical skills, the impact on management, the impact on generic skills and the CCCR’s view of the way the future of OSCM is unfolding.

Jasper addressed questions from roundtable delegates arising from CCCR’s insights into how Data Management can help harmonise design, OSM, on-site assembly and facilities management through horizontal and vertical integrations of supply chain partners by referring to the work of the Berkeley Modular CoBuilder. He presented three scenarios on the impact of OSM on technical skills pointing to; declining skills, continuing skills and emerging skills.

Associate Professor Willy Sher represented Newcastle University’s School of Architecture and the Built Environment at the roundtable. Willy is widely known and respected for his long-serving teaching and industry contributions to construction in Australia. He brought a concerned teaching academic’s perspective to the conversation about the implications for the delivery of the necessary OSM skills by looking at some of today’s teaching realities and challenges. Willy’s comments hit home with academics balancing teaching demand, the development of new and relevant course content, the changing class-room delivery technologies and the expectations of industry that graduates would have the necessary starting skills to set them on a modern construction career trajectory. He canvassed the skilling capacity within the education system and in the workplace. He shared his feelings about the current teaching mode, the value of recorded lectures over power-point presentations, essay mills, flipped classrooms and block teaching. He asked; “what is a uni’ education?”; discussed education versus reality and the role of work integrated learning; and spoke to a case study about translating drawings into buildings.

Willy’s presentation was both salutary and motivational. He called out the challenges confronting all academics and industry to fully engage with making tomorrow’s graduates ‘future ready’. Willy took a number of questions including one on the future role of Industry-based Associations and the need for those bodies to deliver the informed leadership needed to support industry and academia.

Willy’s presentation was both salutary and motivational. He called out the challenges confronting all academics and industry to fully engage with making tomorrow’s graduates ‘future ready’. Willy took a number of questions including one on the future role of Industry-based Associations and the need for those bodies to deliver the informed leadership needed to support industry and academia.

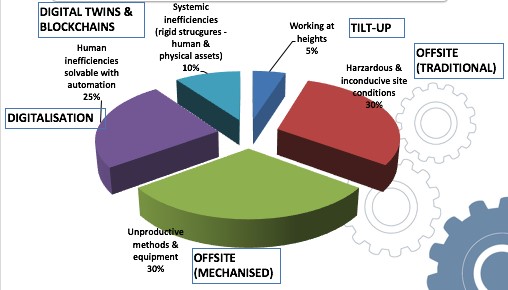

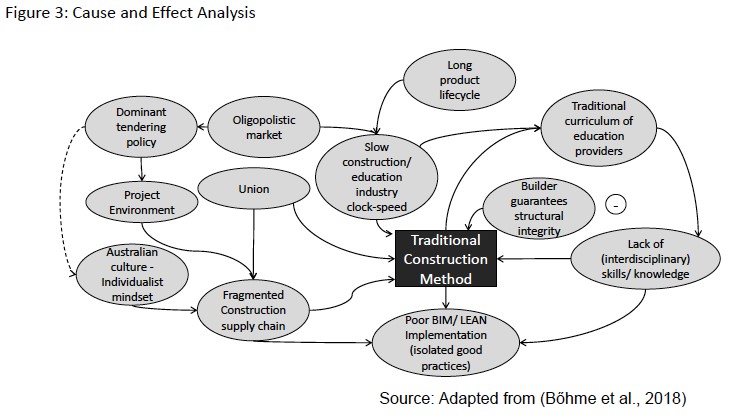

Dr Tillman Bohme is a Senior Lecturer in the University of Wollongong’s Faculty of Business. He is a member of the School of Management, Operations and Marketing. Tillman provided a high-quality Skills Analysis into Construction Supply Chain Reconfiguration. He led by discussing his work involving a System Effective Flywheel involving Integrated Knowledge, Engineering the Means Whereby and Effective Action. Dr Bohme presented a planned versus actual performance case study using a traditional construction method. And then unpacked a cause and effect analysis of the issues confronting the adoption of a viable OSCM sector in Australia.

From this overview Dr Bohme discussed how the Construction Supply Chain (CSC) may be re-configured whereby the system needed to be governed by a clear philosophy e.g. Lean.

He explained the inter-relationships between the parties that need to be embedded, how the tools and technologies to be deployed need to support the system philosophy and how companies and workers in the system need to understand their role in the cause and effect of decision making on the system as a whole. He referenced the work of Gosling et al.,2014 in establishing a framework for lean principles and outlined an explanation of the principles. Tillman then provided an overview of his investigation of the managerial skill sets that would be required in a modernised construction eco-system and how to break the negative reinforcing loop in traditional construction methods.

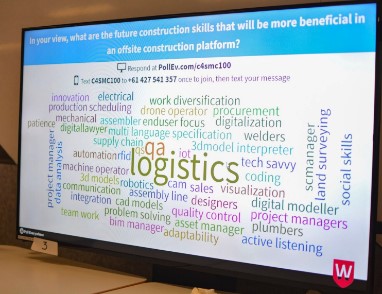

The afternoon roundtable sessions addressed ‘on-site to off-site – implications to construction skill profiles.’ This session was drawn together by each of the Roundtables working through a survey amongst participants to gather their views on how a range of professional, technical and trades skills may evolve in varying scenarios (20%, 50% and 80%) of traditional construction going off-site. Accompanying this survey, each of the participating round tables recorded the frequency of skill by making a WordCloud to be considered along with the survey. Logistics skills topped the list closely followed by production scheduling, procurement, assembler, digital modeler and quality control. The Centre’s PhD team will write up the survey feedback and share with participants.

It was “a hard day at the office” and the final words of summing up were duly shared by Associate Professor Julie Jupp, Head of Digital Design and Construction at the University of Technology Sydney and Marton Marosszeky, Director, Marosszeky Associates and member of the c4SMC Industry Advisory Team. Both were invited to add to the roundtable discussions in their summations.

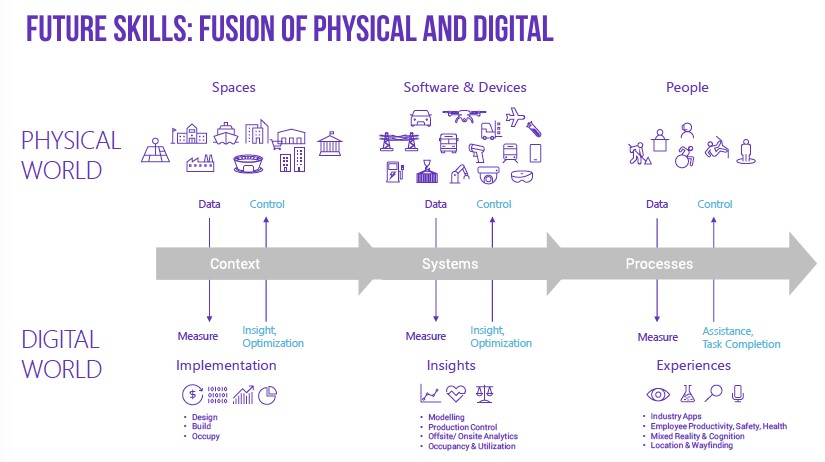

Julie shared her insights into changing models of professional practice as on-site to off-site evolved. She spoke to the continuing changes to activities and workflows, roles and responsibilities, knowledge and competencies and to relationship interfaces. The implications of these changing skills profiles, needed as more on-site goes off-site, will involve re-classification of skill profiles as the mixes of work-packaging change. Responding to these challenges is currently limited by a lack of systems perspectives across the industry and the clock-speed of education adaptation. Julie cited the growing need for more STEM based skills, data-savvy engineers and close monitoring of trends in the attrition rates of the AEC workforce to ensure younger professionals can be retained.

Along the lines of the c4SMC High Achieve Scholarship program, Julie identified the need for more ‘A-players’. This is a constant call by industry that universities need to help incubate the industry leaders of tomorrow – just processing graduates is not good enough. Julie stressed the need for new, modern-industry skills to be adopted across the entire industry capability platform including clients and tenants, academics, building owners, facilities managers, financiers and insurers, asset valuers and certifiers, engineering consultants and of course constructors and fabricators. This would all be about the fusion of future skills, both physical and digital.

Julie’s presentation demonstrated why the c4SMC roundtable addressing the impact of on-site construction moving off-site was just “the tip of the iceberg”. This would be a challenging navigation for most academics who were bounded by the realities of today’s practices and structure. The “jigsaw” she envisioned, providing a way forward to these boundaries, needed to include not only culture-change but “an understanding of the necessary return on investment” all progressive steps need to make. Julie leads a Skills Sync project at UTS called ‘The closing the loop in University-Industry Alliance’.

Marton Marosszeky had the last word. His core message is that this stage in construction industry history book is our ‘collective moment in time’. He acknowledged to enthusiastic and open sharing of the many insights shared at this round table. He acknowledged the uniqueness of the c4SMC initiative and the early positive impact that this initiative was having at Western Sydney University and in contributing to a national conversation about the future of construction like has occurred at this roundtable. He acknowledged both the diversity of insights shared today and the obvious desire to collaborate to help the Australian construction industry to transform, to build the skills that will be needed and the enterprise resilience that is needed.

Marton recapped on the journey of prefabrication whose first way can be traced back to the 1960’s. In his overview of the big issues he sees needing to be addressed are; universities tacit contract with the public to embrace new knowledge and practice, the potential of Lean Quality as a tool to enable clearer thinking and underlying OSCM construction system philosophies and how Lean could be deployed to drive change. This theme was also discussed by Dr Tillman Bohme. Marton pointed to a wave of design and construction thinkers like Brandt and Habraken whose legacies are just as valid today in unlocking modern construction systematisation and a less wasteful and sustainable circular economy.

Marton reflected on Willy Sher’s presentation which challenged academics to shape the future and not reteach the past. He emphasised the need to set measurable goals and to track performance. He spoke to the nexus between standardised work and organisation. He concluded by listing what he saw as the critical issues for construction businesses on an OSCM world;

- Fostering educated costumers v product customers

- OSCM needs a pipeline of work

- There needs to be new clarity on risk allocation

- A revisioning of the roles of general contractors, manufacturers and installers is needed

- A technology adoption leap is essential

- The industry needs to become customer and user facing and less self-facing

- Businesses need better investment planning up-front

- End to end supply chain innovation is fundamental

- Logistics skills will need to be both global and local

- All of construction’s pieces and parts need to be in sync

- Minimising on-site time is the key goal of OSCM

- The industry must re-imagine the attitude it has to compliance and acceptance.

Marton acknowledged the valuable contribution to the inaugural inter-university roundtable.

On behalf of the Centre he extended an ongoing desire to continue to ‘join up the construction conversation’ in the mutual interest of all. He expressed the hope that some collaborative projects may evolve amongst those who joined in today. He expressed the appreciation of all of the Centre’s research candidates who have clearly gained wide ranging new insights into the areas they are investigating. On behalf of the c4SMC industry supporters he wished all who participated a safe journey home, best wishes for the season ahead and for a great 2019.

|  |

|  |

|  |

[i] Reports and links referred to by Professor London

Three reports written for ASCRF China Mission Off site Project are available at:

https://www.dropbox.com/s/4cjzxj31y9krn3g/Current%20State.pdf?dl=0

https://www.dropbox.com/s/bdamppvvifpp3wv/Lessons%20Learnt%20Report.pdf?dl=0

https://www.dropbox.com/s/wtd3t18oj57s1y6/Research%20Roadmap.pdf?dl=0

Link to the Industrialised Building website: https://www.industrialisedbuilding.com/

Link to the video for the Executive Training from the ARC Linkage:https://www.westernsydney.edu.au/scem/school_of_computing_engineering_and_mathematics/research/australian_housing_supply_chain_alliance_ahsca/arc_linkage_efficient_construction

Link to APO website - http://apo.org.au/

RHC Buttons

Mobile options: