c4SMC Industry Engagement provides a wealth of Smart Modern Construction Insights

Over the University Summer members of the academic teaching staff have been visiting sites where the modernisation of construction is unfolding. They have found a number of Western Sydney University Construction Management Alumni at the leading edge. It has been pleasing to find c4SMC investors demonstrating why its time to modernise the industry. Constructors like Andrew Fowler's Austruss is a prime example, but so are firms like Prime Construction, Hansen Yuncken, StrongBuild, Bedrock and Qanstruct.

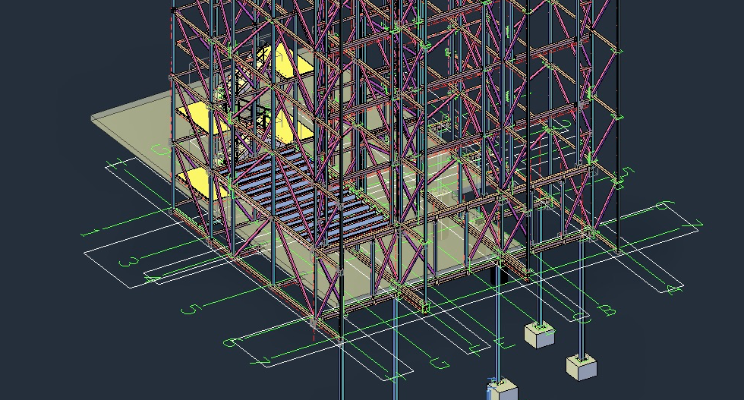

Austruss fabricated a 6-storey light steel frame apartment building at their southern highlands factory and erected this on Boyce Construction's Dulwich Hill project in a little over 3 weeks (excluding the Christmas close). Developer Greg Boyce and Andrew Fowler are WSU - CM Alumni. The video below is a time lapse of progress.

Associate Professor Mary Hardie, Senior Construction Lecturer Phil Love and lecturer Dr. Brendan Kirkland have made several trips to site to see first hand the innovations and rapid construction techniques being displayed. Andrew Fowler is using this project as a proof of concept opportunity, before the wider roll out of his system in 2018.

StrongBuild are leading the way with rapid mass timber construction on the Aveo project at Bella Vista. This is the second high rise residential project that Adam Strong and his team have delivered. Strong points to the need to understand the technologies involved, the logistics, a commitment to quality and how production in the factory must be organised to make the on-site process efficient and reliable. c4SMC Industry Engagement Lead, Adjunct Professor David Chandler and PrefabAUS CEO Warren McGregor visited StrongBuild's Aveo project to see progress first hand.

Out in the Western Suburbs the CM Team found Prime Constructions and Qanstruct both demonstrating how smart modern construction techniques were being applied to building huge warehouse complexes involving sophisticated concrete placement technologies to deliver super-flat floors suitable for all types of automated place and pick equipment to serve the 3PL market (Third Party Logistics). These buildings demand specialist know-how to deal with massive footprints of 25,000m2, huge roof areas involving complex load designs for wind-uplift, huge stormwater run-offs and even the load of 200 mm of hail. The Centre will arrange a larger group site tour of these projects in April. Those interested should let Associate Professor Hardie know.

Meanwhile in North Strathfield CM Alumni Charbel Azar is on the site management team for a massive timber school building for the Catholic Church. Our academic team was able to visit the site on two occasions thanks to builder Stephen Edwards. Charbel shared the challenges of integrating an overseas supplied pre-manufacture build as an extension to an existing school building. That said, the quality of the off-site manufacture and the final building demonstrates just how fast traditional construction is moving off-site and how the industry will have to deal with new logistics and planning.

These are just a few examples of the Smart Modern Construction stories that are now occurring in our industry every day. The Centre will be joining up all of these construction conversations in the research projects that are now commencing and via initiatives such as the SmartBuild-Lab (SBL)that is now entering the planning phase. The SBL will be developed on a 5000m2 site the university has set aside for this full scale construction demonstration platform that will display how the off and on-site inputs of modern construction can come together to achieve smarter, faster, better, safer and more assured outcomes. The NSW Timber Development Association has given expression of intent to be the first-user of this platform that will also be offered to the steel and pre-cast concrete industries to display their modern construction innovations.

The Centre is committed to inform future constructors of the practical and technical issues that they will encounter when they enter the industry. The industry has made it clear that they are looking for high achiever future-ready constructors who will help make a positive impact in the enterprises they will join, early in their careers. The first round of c4SMC High Achiever Scholarships are now open for application. Associate Professor Mary Hardie is co-ordinating the application and award of these scholarships.

The Centre will regularly report on the visible evidence of Smart Modern construction being displayed by the Centre's investors and collaborators. The next article will deal with supporters Hansen Yuncken, Bedrock, Weathertex and Health Planners TAHPI. These organisations and more can be viewed on the Centres web-site. See the link below.

Written by:

David Chandler OAM

Adjunct Professor at Western Sydney University

10 February 2018

RHC Buttons

Mobile options: